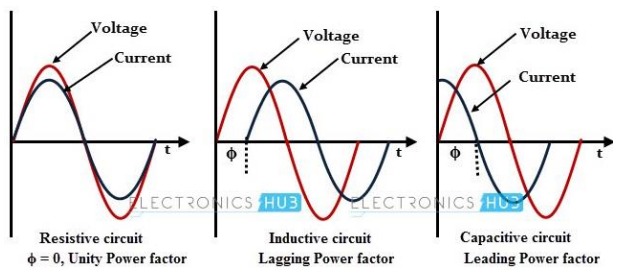

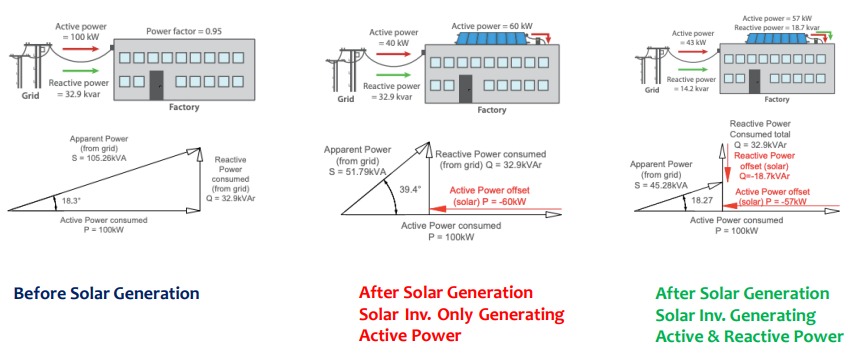

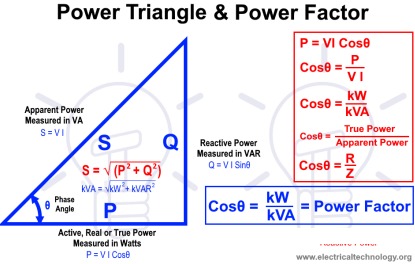

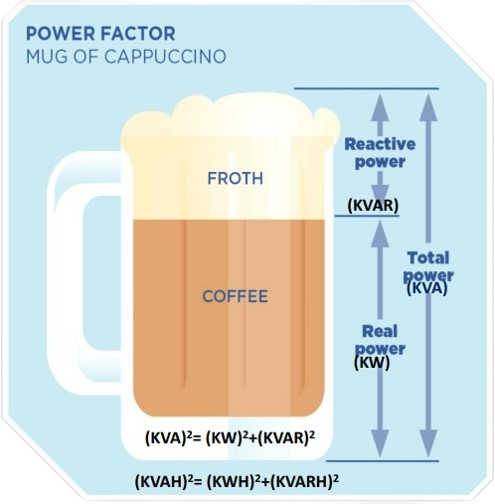

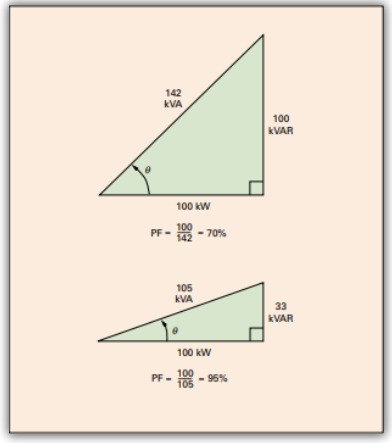

Power Factor is the ratio of real power (KW) to apparent power (KVA) in an electrical system, indicating efficiency. CR Energy offers services involving calculations for KVA, KW, and KVAR, using formulas like (KVA)^2 = (KW)^2 + (KVAR)^2 and (KVAH)^2 = (KWH)^2 + (KVARH)^2 to optimize energy usage.

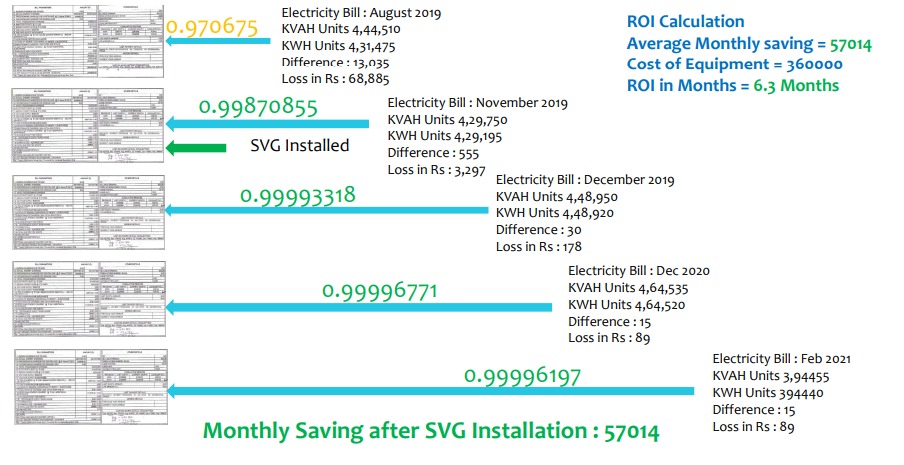

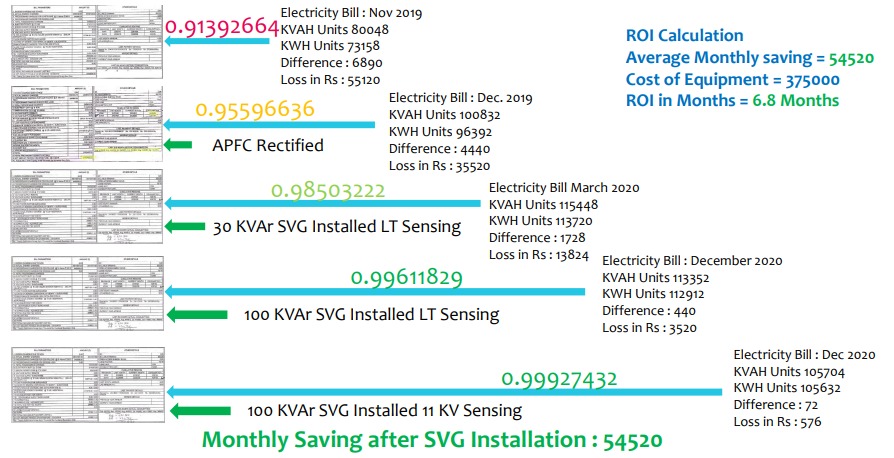

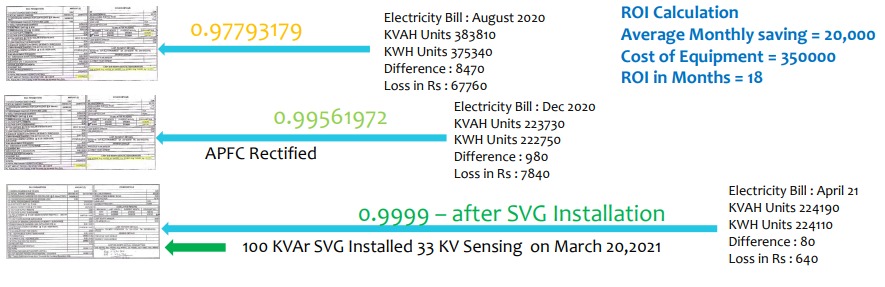

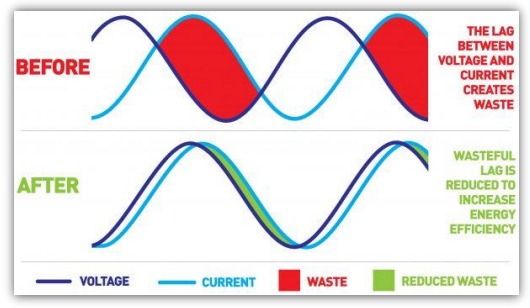

Lower electricity bills by improving power factor and reducing reactive power demand.

Reduce equipment wear and tear, extending its operational life and improving overall performance.

Stabilize voltage levels and reduce power losses, ensuring smoother and more reliable operations.

Optimize energy usage and reduce strain on the power supply, leading to more efficient industrial processes.

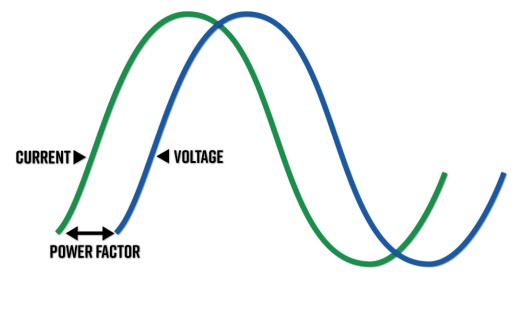

Power factor is the relation between the kW and the kVA

drawn by an electrical load where the kW is the actual load

power and the kVA is the apparent load power.

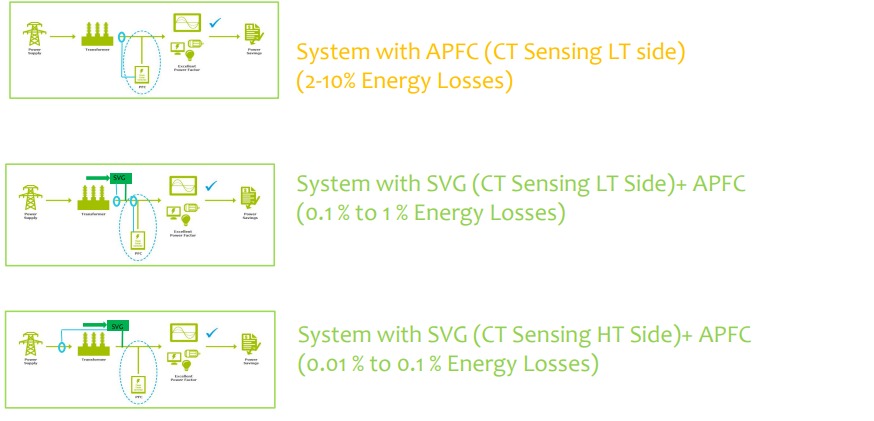

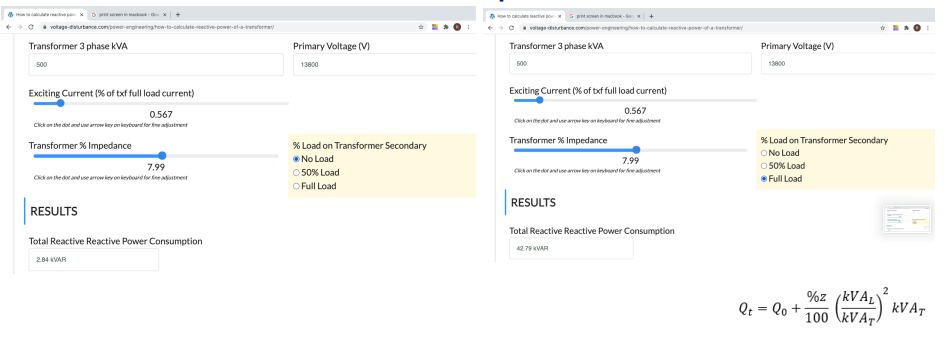

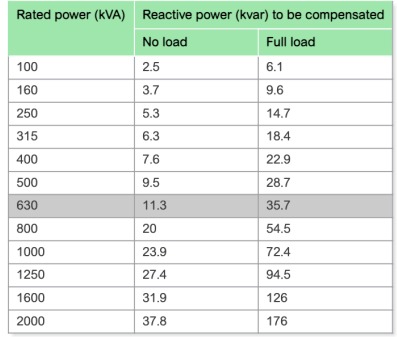

The reactive power drawn by power transformer could be as high as 5% of the transformer rating when supplying full load current. Power factor at the primary of the transformer is usually lower than what is measured at the secondary due to this reactive

power requirement of transformer.

During no load condition of transformer, the excitation or magnetizing current flow in the primary winding of the transformer. This excitation current is made up of large component of magnetizing component of current (Im) which is in quadrature with the applied voltage and comparatively small in phase component of current (Ie) which is in phase with the applied voltage. Thus due to large magnetizing component, power factor of the transformer will be very low. Power factor will be usually 0.1 to 0.2 lag

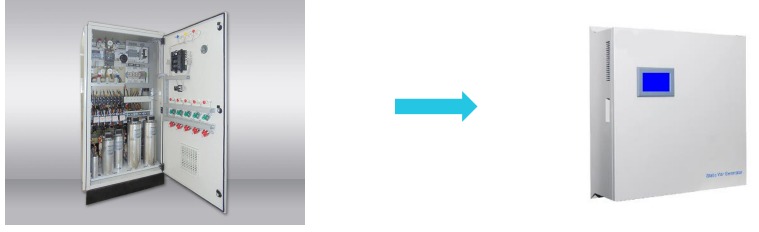

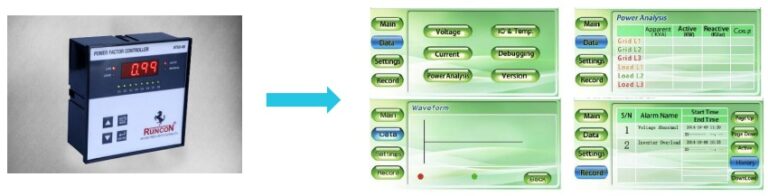

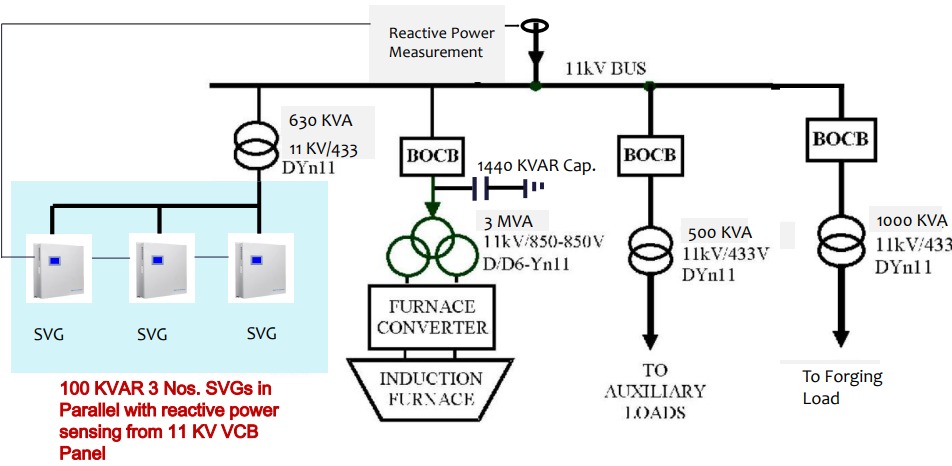

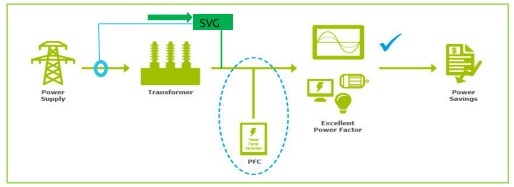

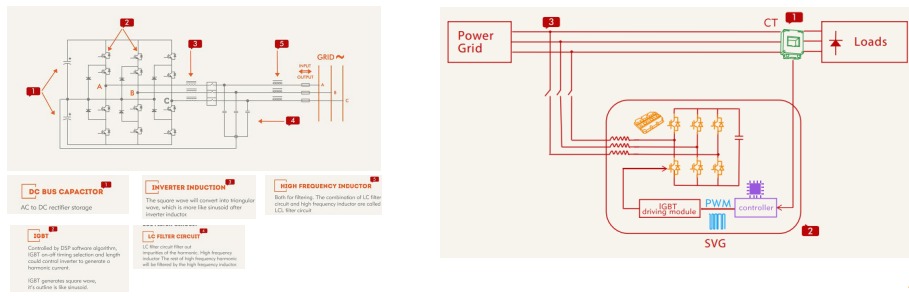

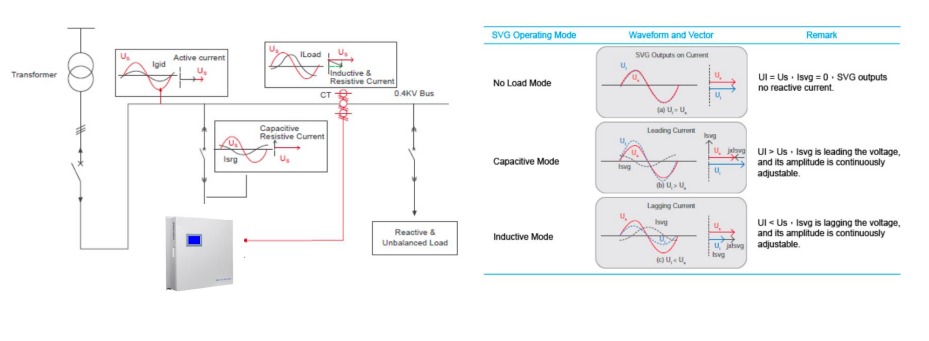

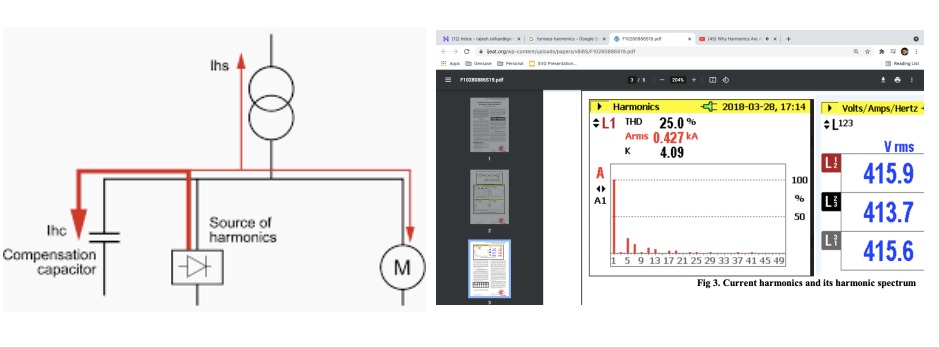

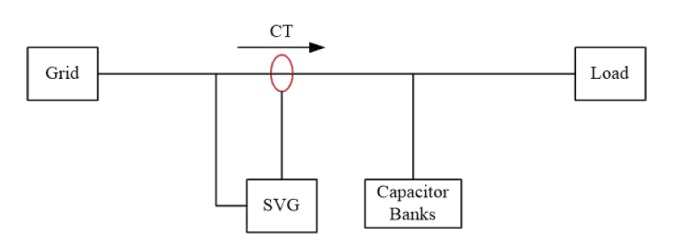

Load current is detected through external CTs and fed to the internal Controller where an Instantaneous Reactive Power algorithm separates the active power from the reactive power. A compensating reactive power requirement is dynamically and accurately calculated and sent to the IGBT control where a PWM signal is generated at a switching frequency of 20kHz. A compensating capacitive reactive power or inductive reactive power is controlled by the manipulation of the DC bus voltage in comparison to the AC line voltage. Thus a capacitive current or inductive current will flow, creating a reactive power exchange with the network voltage level

It operates by detecting the load current on a real-time basis through external CT’s and determining the reactive content of the load current. The data is analysed and the SVG’s controller drives the internal IGBT’s by using pulse width modulation signals to make the inverter produce the exact reverse reactive current of the corresponding load reactive content. This is injected to the grid to compensate the reactive content of the load current . By adjusting the output voltage amplitude and phase angle or by directly controlling the AC side current, the SVG can absorb or generate var according to the load reactive power or the grid

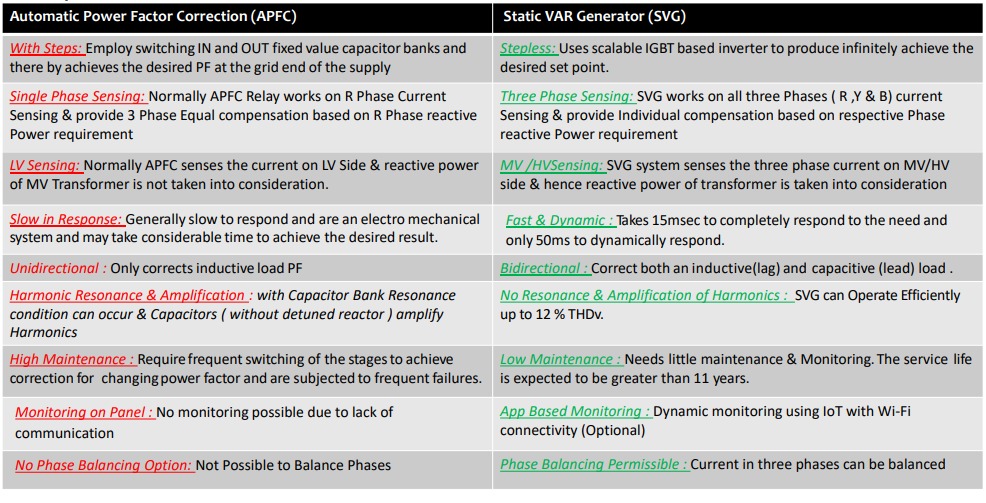

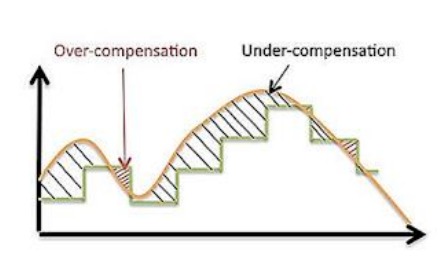

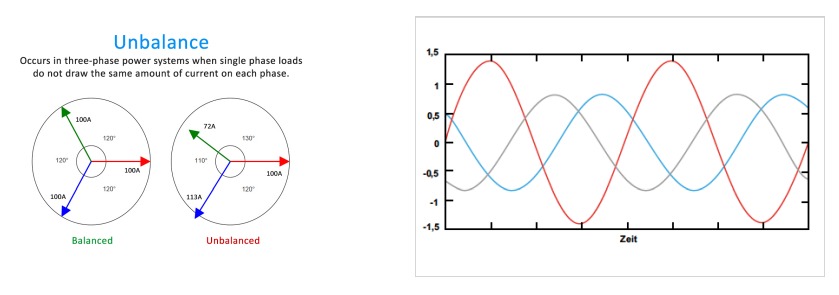

A traditional switched capacitor type PFC system measures one phase and then provides stepped kVAr compensation to all phases based on the measurements taken from the one phase being measured. The other two phases all receive the same compensation, irrespective of what the other two phases actually need. The SVG measures all 3 phases and provides specific dynamic kVAr compensation each phase.

A load that has a lagging power factor is, by convention, said to be receiving reactive power from the source. A load that has a leading power factor is, by convention, said to be delivering reactive power to the source. … Therefore, lagging reactive power is positive and leading reactive power is negative. SVG Compensates both inductive and capacitive loads